Proven Welding

Automated Solutions

Experience, Knowledge, Reliability,

Service, Technology, Solutions

Automated Welding Systems

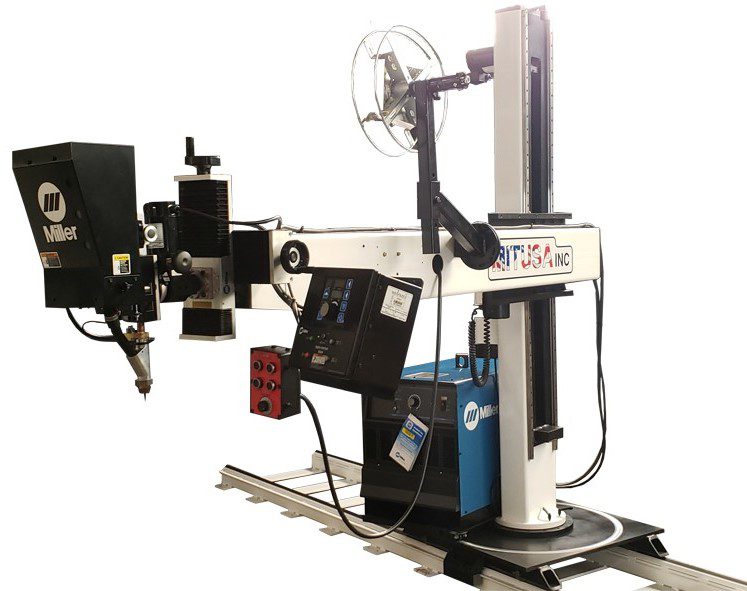

MITUSA Inc. is a highly qualified American based manufacturer of engineered, precision, fixed welding automation systems. Our in-house capabilities include structural steel, tooling, electrical, hydraulic, and pneumatic design. We pride ourselves on manufacturing products to the highest of standards using modern equipment and techniques. MITUSA Inc has a several Hass machining centers, multiple planers, CNC plasma cutting, multiple welding power systems and processes, vibratory stress relief, laser measurement system, and a 40 ft enclosed painting booth.

Applying hundreds of years of experience to your automated welding needs, our team is your single source supplier.From initial concept to fabrication and manufacturing of a reliable automated welding solution, that’s what we do.

DREAM IT, WE CAN BUILD IT

Products we offer for welding automation solutions

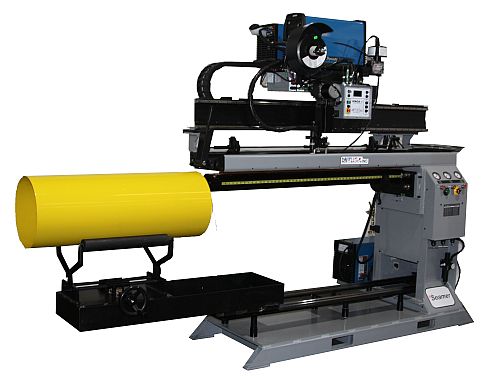

MITUSA Inc. manufacturers a diversified line of longitudinal seam welding systems. Our seam welders can handle cylinders or plate, thin to thick, weldable metals from 3 inch to 40 ft in length. MITUSA Inc can also offer material handling for loading and unloading. We offer several weld planishing systems to flatten or cold work the weld bead. Bench style, gantry, and a seamer tabletop design are unique products offering a proven solution.